Methodology

for Validation and Documentation of Vehicle Finite Element Crash ModelS for

Roadside Hardware Applications

ABSTRACT

Researchers

involved in finite element method (FEM) crash simulation of Roadside Hardware need

efficient, validated FE models of vehicles. The National Crash Analysis Center (NCAC) funded

by the US Department of Transportation have

been developing and releasing to the public domain numerous vehicle FE models.

These models are modified and combined with other models to develop specific

simulation scenarios. Users of the models regularly make modifications to the

basic vehicle model according to their particular simulation requirements. A

cooperative effort between the National

Transportation Research Center (NTRC), Oak

Ridge National Laboratory (ORNL), Battelle,

and NCAC was initiated to explore the possibility of updating and enhancing the

kinematic and structural accuracy of these basic vehicle models. This document

outlines the methodology used in evaluating, validating against experimental

data and updating NCAC's Ford F800 Single Unit Truck FE model. A new Hypertext

Markup Language (HTML)-based documentation has been developed to facilitate the

model adoption and understanding of prospective users. The overall methodology

used by the participants - from evaluation to validation to documentation - is

outlined here can be applied to other basic vehicle FE model

currently available to users, and in our opinion could further facilitate

crashworthiness research.

INTRODUCTION

It has become a standard practice in roadside hardware

research to evaluate new and existing designs with computational simulations

using large and complex models based on the Finite Element Method (FEM) [1].

Building a FE model of an entire vehicle

of any kind is a considerable undertaking. A significant technical expertise

and FEM tradecraft is needed to develop a computationally feasible and

practical model that replicates the main kinematics of the vehicle and the

deformation response due to the impact loads.

The most challenging aspect of model

development is the constant tradeoff between the real world complexity of the

vehicle and engineering simplification of its model that should not compromise

the final goal of a sufficiently accurate model suited for its purpose. This

tradeoff process evolves with advances in computing and, therefore, the already

developed models may need to be updated not only to remedy some of their

drawbacks, but also to bring them up to the ever-improving levels of

computational capabilities.

A FE model of a representative Single Unit Truck (SUT)

was developed by the FHWA [2]. The model has been released to public use and

has been used for numerous computational studies of roadside hardware. The

model's primary purpose is to be used as a bullet object for computational

evaluation of road safety hardware, and as such it does not warrant the

complexity ordinarily employed in vehicle crash analysis models. In fact, too

much complexity in a bullet model may be detrimental to its primary purpose

because of an increased computational burden and structural failures in the

bullet that may overshadow the target's response. Therefore, possible

modifications of the vehicle model must always be evaluated within the context

of the roadside model development.

The objectives of this research were to conduct an

evaluation of the SUT model with respect to its ability to accurately simulate

its interaction with roadside safety hardware, to identify areas of possible

improvements based on comparison of simulations with crash experiments, and

consequently modify and update the model to improve its accuracy and take

advantage of current advances in FEM.

To be able to use the model efficiently and appropriately,

a prospective user has to understand its structure and modeling decisions made

during its development. The traditional user's manual format is not very

effective for describing a three-dimensional model, the interconnections

between different parts and their participation in different sub-modeling

entities. Therefore, a long lead-time is necessary for a new user to be able

to use the model with sufficient confidence to know that the perceived impact

configuration is indeed the modeled one. We have developed an interactive,

web-based User's Manual of this vehicle FE model to simplify this learning

process and make the model more transparent to new users.

This vehicle model is fairly well suited

to its purpose as a bullet vehicle. For example, on a 2-cpu 1.8 MHz. Dell

workstation with the Linux operating system, the truck-model-only run time

using LS-DYNA 970 [3] was 2 hours 40 minutes clock time to run 226 milliseconds

of simulation time. The nominal time step was about 4 microseconds. This appeared to be a

good trade-off between mesh refinement and speed.

Representative Single Unit Truck for

Roadside Hardware Analysis

Due to practical considerations in roadside hardware analysis, the

number of vehicle FE models used and developed is limited. The process

involves selection of a representative vehicle for each vehicle class, and

developing respective FE models. Therefore, the model and available

experimental data may not always coincide but it is assumed that the

differences in the structural behavior between models of the same class are

negligible with respect to the roadside hardware response and performance. The

Ford F800 Series Truck was selected as representative of the SUT vehicle class.

The available experimental data for the SUT category were obtained using a

variety of similar size trucks including; GMC, Chevrolet, Freightliner, and

International. The vehicle is ballasted to the correct weight for the test

level requirements.

A cursory inspection of several makes and

models of SUT's at a truck dealership revealed generally more similarities than

differences. The chassis were all parallel-rail frame types with front and

rear leaf spring suspension. They all had V-8 diesel or gasoline engines, and

all had dual-wheel rear axles. The cargo bodies are mounted on a series of

lateral C- or I-Beams which are welded to C-Channels that run parallel and

directly atop the chassis main frames. There typically is a wooden member as a

buffer between the Parallel C-Channels and the main chassis frame rails. Large

U-Bolts fasten the Cargo-body C-Channels to the chassis main rails. The GMC

7000 SUT used in the TTI test 7147-17 was typical of this design and had an

empty weight of 11470 lb. The NCAC F800 Model was also of this general design and had

an empty weight of 11051 lbs.

Outline of the SUT Model Analysis Process

The

analysis of the SUT model was conducted on evolving model versions as they were

being developed by NCAC. The initial analysis of the model resulted in several

suggestions and modifications that were subsequently implemented by the NCAC.

The evaluation of the early versions of the SUT model consisted of the

following steps:

- Preliminary evaluation of the SUT models using

FEM simulations

- Comparison of the simulations with the crash

experiments

- Identification of the model areas critical for

its performance in roadside hardware analysis

- Analysis of the SUT service manuals with respect

to FEM modeling approaches

- Analysis of the SUT model material models

- Analysis of the connectivity and joint models

- Analysis of the suspension and its possible

failure modes

- Model modification - analysis of the new results

and recommendations for updates in the model

The analysis and simulations of the early model

versions lead to recommendations for the model updates that were later

implemented by the original developers. The updated model was then used as a

platform on which the final analysis and modifications were performed.

SUT Material Models

Even the FEM models with large numbers of elements

will not be able to produce realistic results without realistically modeled

material behavior. One of the important areas of the SUT model update is the

implementation of more detailed material model assignment and material

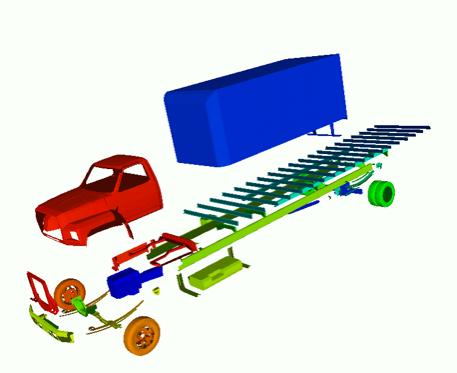

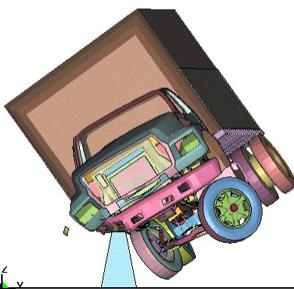

properties. An exploded view of the SUT parts that are assigned materials is

shown in Figure 1.

Figure 1

SUT computational parts

The vehicle is built on a main longitudinal rail

structure that acts as its backbone. It is therefore important to accurately

model the geometry and the material of the rails. The material of the rails is

specified in the Service Manual as the High Strength Low Alloy (HSLA) steel of

yield point 350 MPa. The material data available from the Auto/Steel

Partnership [4] and American Iron and Steel Institute [5] was used to enhance

the existing material model.

The new material model includes the effects of strain

rate sensitivity, which is very important in steels. Mild low-carbon steel

(DQSK) is primarily used in body structures and, by volume, constitutes the

largest part of the vehicle. The new model also adds a strain rate sensitivity

effect. Other significant material models implemented were the SAE 5160 bracket

and spring steel, SAE 1541 forged axle steel, Hot Rolled bumper steel and medium

Carbon alloyed SAE Grade 8 steel for nuts and bolts. Parts made of each of

these materials can be interactively viewed using the Virtual Reality Markup

Language (VRML) version of the documentation.

The most commonly used approach to modeling strain-rate

sensitivity of steels in automotive crash simulations is to use isotropic

plasticity models with a rate sensitivity component that has moderate

requirements on the experimental program. The types of material models that

are frequently used are the Johnson-Cook model [6], the Zerilli-Armstrong model

[7] and the piecewise linear strain rate sensitive material model [3]. The

models are appealing because they have been implemented in commercial codes

used for crash simulations and have a relatively small number of material

parameters that must be determined by experiments.

The most commonly used strain rate dependence material

model in crashworthiness simulations of steel structures is the piecewise

linear plasticity model. In this approach, effective strain-stress curves from

experiments are directly used in the computational material models and require

the least amount of effort for material model development. In simulations, for

a given rate of strain, the resulting stress in the plastic region is linearly

interpolated between the stress-strain values that were experimentally

determined in strain rate tests.

The computational model fits experimental data

exactly, but whatever testing artifacts or errors are contained in the

experimental data will be carried over to the simulations. The highest strain

rate in the experimental data acts as a saturation plateau for strain rate

effects. The strain rate dependent model for the HSLA 350 steel used in the

main rails of the SUT were developed by the Auto/Steel Partnership [4] and are

shown in Figure 2. The dashed curves show the results from the quasi-static

uniaxial tensile experiments.

Figure 2

Material parameters for HSLA350

Vehicle – Infrastructure Asset

Interaction

An FHWA-funded study was undertaken by Battelle and ORNL to model

and assess different scenarios of truck vehicle run-off-road collisions with

roadway infrastructure elements, vehicle structural modes of failure, and

subsequent vehicle stability. The focus of this work was to identify areas of

the NCAC Ford F800 Single Unit Truck (SUT) model that was available at the time

that could be improved to make it more immediately useful as-downloaded from

the NCAC Finite Element Model archive. To accomplish this, Battelle worked

with Oak Ridge National Laboratory, the FHWA-sponsored National Crash Analysis

Center (NCAC) and other Centers of Excellence (COE) in Finite Element Crash

Analysis.

The vehicle model improvement study focused on impacts

with rigid barriers because this kind of test captures the vehicle model

behavior rather than the barrier response. Several simulations were run by

Battelle and ORNL during the course of this work and a number of vehicle model

improvements were suggested and implemented. The

procedure that was established to validate and verify the SUT model also will

provide the methodology for validation and verification of other heavy-vehicle

models currently under development at NCAC.

The experimental data collected on Single Unit Truck

(SUT) came from full scale tests performed by the Texas Transportation

Institute (TTI). The crash analysis simulations of the Texas Transportation

Institute (TTI) Crash Test No. 7147-17 – SUT impacting Single Slope

Concrete Bridge Rail, were performed. The crash test vehicle was an 18,000 lb.

GMC 7000 Single Unit Truck (11470 lb curb weight plus 6530 lb ballast load).

The vehicle was impacted into a single-slope bridge rail at 51.3 mph, at an

impact angle of 17.9 degrees

Figures 3 through 5 show (in very abbreviated form) of

the general level improvement achieved in this vehicle model's fidelity.

Figure 3 shows one snapshot in time (0.672 seconds after impact) from the crash

test experiment. Figure 4 shows the original vehicle model's response at 0.672

seconds after impact and Figure 5 shows the improved model's response at 0.672

seconds after impact.

Figure 3

TTI Test at Time = 0.672 Seconds After Initial Impact

Figure 4 Original

F800 SUT Simulation at Time = 0.672 Seconds After Initial Impact

Figure 5

Improved F800 SUT Simulation at Time = 0.672 Seconds After Initial Impact

SUT Model Documentation

Vehicle

and roadside hardware FEM models from DOT and NCAC are available in public

domain so that they can be modified and combined with other models. The

availability of verified FEM models greatly facilitates research in the

transportation field. Perhaps the biggest obstacle in adoption of the FEM

models is their complexity and the respective startup time before they can be

confidently used in new impact scenarios. Since the computer simulations are

very tolerant to modeling errors, even the verified FEM models can be

inappropriately used if they are not fully understood.

Ever increasing computing capability leads to

correspondingly larger and more detailed FEM models so that the written

documentation cannot efficiently convey the model's structure and development

considerations and keep up with inevitable model updates. One of the

objectives of this research was to introduce new internet-based technologies to

the model documentation and presentation. The FEM vehicle modeling is

inherently complex and three-dimensional so the ability to effectively view the

model's information is very important.

To view the vehicle models, a combination of Virtual

Reality Modeling Language (VRML) and Hypertext Markup Language (HTML) was used

to build the Visualization Module of the documentation package. Additionally,

the Visualization Module allows for easy access of other tools within the

documentation package. Although new languages for three-dimensional computer

environments have been proposed, VRML with all its limitations is still

prevailing standard. A VRML file format is a plain text format that describes

the shapes and their properties within a 3D world. This file only specifies

objects and shapes within a virtual environment; it does not handle the

navigation and the interaction. Moving through the world, rotating objects,

and similar functions are handled through a VRML player, an application that

displays the VRML file.

Other important considerations are the size of model

documentation and the ability to efficiently transmit that information in

today's network environment. The dynamics of computing development will

inevitably lead to faster networks and better ways of model presentation, but

it is reasonable to expect that they will be based on three-dimensional modes

of data display. The VRML mode of interaction with the automotive

crashworthiness models was also explored in Reference [8] and briefly reviewed

below.

Vehicle geometry is converted into a VRML file by a

Perl script that sorts the parts, assigns them positions and rotations, colors

them, and assigns them appropriate behaviors. Due to this automated process it

is possible to quickly export new versions of the vehicle model to VRML format

and post them for viewing and analyzing on the World Wide Web. A virtual

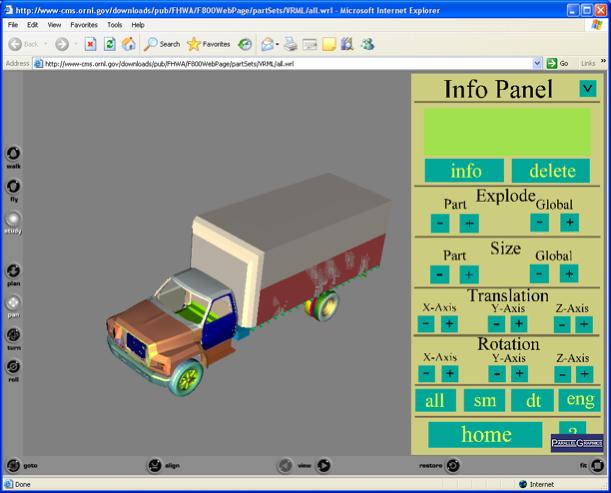

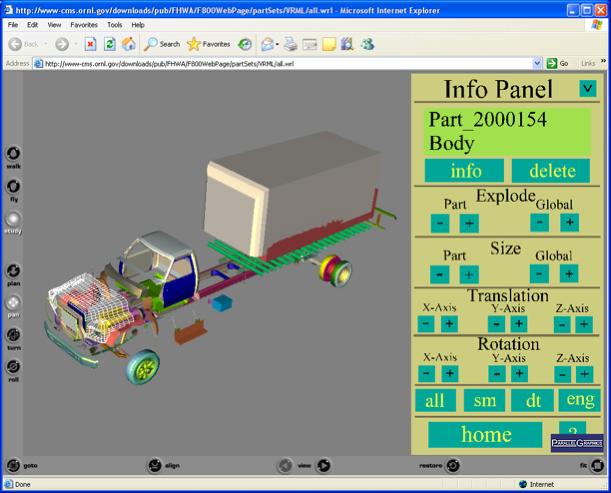

control panel constantly follows the user inside the VRML world (Figure 6). The panel allows the user to select individual

vehicle parts, examine their mesh makeup, move, rotate, and eventually call up

an information page about the part and further cross-referencing as its

participation in different contact sets, element types, etc. The explode

feature separates the individual parts, allowing the user to get a good idea

about the interconnectivity of the vehicle (Figure 7).

Figure 6

VRML Interface to the Documentation

Figure 7

Exploded View with Selected Part

The name of the part and the subsystem it belongs to

are also displayed in the control panel. By using this control panel, the user

can easily navigate through the vehicle and gather information about it. The

delete function allows the user to remove any parts that are obstructing the

area of interest. This is a common occurrence - especially if user wants to

examine a cramped area such as the engine compartment. Additionally, the user

is able to examine a part's mesh composition by selecting it. These features

are easy to add, delete, or alter, due to the object-oriented design of the

VRML interface.

We

have organized the model documentation in 5 categories

- Part sets (subsystems)

- Parts

- FEM element types

- Material models

- Contacts

Other

groupings are clearly possible (i.e. connectivity models) and can be added to

the existing documentation.

The part sets categories are selected based on their organization

in SUT Service Manuals. The parts sets can be viewed in both HTML and VRML

modes. The HTML documentation is programmed as the staring point due to the low

data transfer requirement. As the user searches for more details, the VRML

interactive environment is offered to clarify the details of spatial

information.

SUMMARY

The main objectives of

this research were to conduct an in-depth evaluation of the Single Unit Truck

(SUT) finite element model with respect to its ability to accurately simulate

its interaction with roadside safety hardware and to identify areas of possible

improvements. The model's primary purpose is to be used as a bullet object

for computational evaluation of road safety hardware. The modifications of the

vehicle model were evaluated within the context of the roadside hardware model

development.

The analysis of the

model and comparison between simulations and tests lead to recommendations for

the SUT model modifications that were implemented by the original developers of

the model, National Crash Analysis Center (NCAC) and participants in this

project, Battelle, Oak Ridge National Laboratory and University of Tennessee.

The goal of the project was also to establish a methodology for validation and

verification of the finite element models used in roadside hardware analysis so

that it could be applied to other vehicle finite element models currently under

development.

The model and the

project developments are documented in an HTML based environment that allows

for dynamic visualization and interaction with the model. The user can view and

analyze all the main components of the model and their interactions. The goal

of the interactive 3D environment is to make the model more transparent to the

end users and to facilitate transfer of the developed models and technologies

to the end users.

Acknowledgements

This Heavy Vehicle Safety Research project was sponsored by the U.S.

Department of Transportation/Federal Highway Administration under

cooperative agreement #DTFH61-03-X-00030 with NTRCI.

Use of the supercomputers at

the ORNL Center for Computational Sciences (CCS) is gratefully acknowledged.

Our thanks to Roger Bligh of

the Texas Transportation Institute for his generous contribution of the

experimental test data that was essential to this study

Our thanks to

NCAC staff – Dr. Leonard Meczkowski, Dr. Dhafer Marzougui, and Dr.

Cing-Dao (Steve) Kan for their continuing support, help and advice on this

vehicle model.

References

1.

Belytschko,

T., Liu, W. K., Moran, B., Nonlinear Finite Elements for Continua and

Structures, Wiley, 2000.

2.

National

Crashworthiness Analysis Center Model Archive, http://www.ncac.gwu.edu/archives/model/index.html, 2003.

3.

Hallquist,

J. O., LS-DYNA3D, An explicit finite element nonlinear analysis code for structures

in three dimensions, LSTC Manual, 1995.

4.

Mahadevan,

K., Fekete, J. R., Schell B., McCoy, R., Faruque, O., Strain-Rate

Characterization of Automotive Steel and the Effect of Strain-Rate in Component

Crush Analysis, SAE paper 982392, 1998.

5.

Simunovic,

S., Shaw, J., Aramayo, G., Material modeling effects on impact deformation of

ultra light steel auto body, SAE Paper 2000-01-2715, 2000.

6.

Johnson,

G. R. and Cook, W. H., A Constitutive Model and Data for Metals Subjected to

Large Strains, High Strain-rates and High Temperatures, Proceedings of the

Seventh International Symposium on Ballistic, The Hague, The Netherlands, 1983,

pp. 541-547.

7.

Zerilli,

F. J. and Armstrong, R. W., Dislocation-Mechanics-Based Constitutive Relations

for Material Dynamics Calculations," Journal of Applied Physics V 61 (5),

pp. 1816-1825, 1987.

8.

Bobrek,

A., Simunovic, S., Aramayo, G., Collaborative Toolkit for Crashworthiness

Research HICSS-34, Minitrack on Developing and Deploying Collaborative Problem

Solving Environments 2001.